Metal Tube Cleaner Spring Tension vs. Projectile’s Patented Design

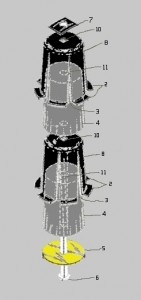

Our patented metal tube cleaner is designed to remove deposits such as mud, silt, slime, manganese, calcium, and other deposits from the inside of condenser and heat exchanger tubes without harming the tube surfaces. Our patented design employs rubber bushings. These allow for a longer life expectancy, approximately 15 passes, and these bushings allow us to adjust the poundage in order to perfectly fit each unique tube size. Projectile sizes are available for tube sizes 5/8” to 1 ¼” (15.875mm to 31.750 mm) outer diameter (O.D.).