Condenser and heat exchanger tube fouling can cause serious issues for both equipment performance and overall equipment lifecycle. Removing tube fouling is essential to proper maintenance of equipment. To successfully remove fouling, it is important to have a competent and direct strategy for doing so. An essential part of this strategy is choosing the correct tube cleaner to match the type of tube fouling.

Soft Deposits

Softer deposits generally come in the form of biological fouling and loose sediments such as silts, algae, sea weed, mud, and slimes. Different types of these mud and slime fouling have different qualities, but the main characteristic of these tube fouling types is that they are not adhering tightly to the tube wall and thus can be cleaned with a softer tube cleaner. There are two types of tube cleaning devices for soft deposits: plastic pig tube cleaners and nylon brushes.

Plastic Pig Tube Cleaner

The plastic pig tube cleaner should only be used on the softest of deposits. The plastic pigs are designed with seven polymer blades that are durable enough to remove soft fouling but will pass over any hard depositions. Slits on the blades insure that water flushing occurs in front of the tube cleaner.

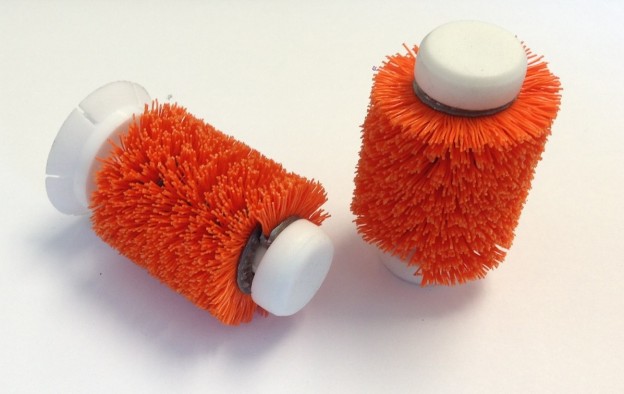

Nylon Brush Projectile

Nylon brush tube cleaners are the best choice for soft deposits. These have been tested to remove twice as much debris as plastic pigs. The durable nylon bristles scrape the tube surface to agitate fouling and water flushes the loose debris after it is agitated. The outer diameter of the brush is slightly oversized for the tube inner diameter which insures a proper fit in each tube. Nylon brush tube cleaners come in both bi-directional, which can be shot through the tube in either direction and finned-end models, which are shot only one direction. The nylon brushes also come in various lengths. The standard length is 1.5 inches, but an XL version can be made that is 3 inches. Nylon brushes are also flexible enough to be used on internally enhanced and rifled tubes.

100% water propulsion is recommended with both plastic pigs and nylon brushes, but if necessary air can be used.

Medium Deposits

Medium deposits include light levels of mineral scaling and heavier sedimentary deposits such as sand. In these cases we recommend our patented plastic projectile tube cleaner.

Plastic Projectile Tube Cleaner

The plastic projectile comes equipped with two thick polymer blades. These blades each have six points of contact covering the circumference of the tube. The blades are specifically cut to match each tube’s inner diameter. Both blades are affixed to a central shaft and are supported by rubber bushings. The bushings allow the blades to fatigue less and also add tension to the tube cleaner so that it provides a more effective cleaning. The projectile is successful at removing light mineral scaling but is not designed to remove heavy scale deposits.

Only 100% water propulsion should be used with plastic projectiles.

Hard Deposits

Hard deposits come in many forms, depending of the process of the heat exchanger. The most common types of hard deposits in cooling water systems, like condenser tubes, are mineral scaling. During heat transfer, minerals leach out from the cooling water and attach to the tube material. If not handled properly, this deposition can become very thick and hard. Examples of common mineral scaling include:

- Calcium carbonate and other calcium based scales

- Manganese

- Silicon in the form of silica based tube deposits

- Oxides

Hard deposits are also very common in the refining and chemical industry, and these deposits depend on the process being used. These can include petroleum-based deposition, coke deposits, wax, and polymer-based deposits. Other forms of hard tube deposits can include macro-fouling such as zebra mussels. In all these cases, these deposits need to be removed with an aggressive tube cleaner. The two tube cleaners that should be used for hard deposits include our patented metal projectile and twisted wire brushes.

Metal Projectile

The metal projectile consists of two carbon steel blades each with six points of contact. The blades are specifically cut to perfectly match the inside diameter of the tube, thus insuring a proper cleaning without damage to the tube surface. This metal tube cleaner utilizes rubber bushings to support the blades and provide a more aggressive cleaning. This design is patented and is the only design on the market that is adjustable. When removing deposits, the blades scrape under the deposit that is attached to the tube and successfully peels it away so the tube base metal is exposed. This design has been independently tested numerous times and has proven to be the most effective metal tube cleaner at removing hard scaling.

Twisted Wire Brush Tube Cleaners

Twisted wire brushes are brushes with metal filament. These brushes can be made with an array of filaments depending on the application, including the most common stainless steel brushes and less common carbon steel and brass brushes. Twisted wire brush tube cleaners are effective at removing hard scaling such as the types described above. In most cases, metal projectiles are more effective but in select cases, such as very gritty deposits and internally enhanced tubes, twisted wire brushes are much more effective.

Only 100% water propulsion should be used with Metal Projectiles and Twisted Wire Brushes.

Special Tubes

Special tube types such as utube heat exchangers and internally enhanced tubes offer special challenges and special tube cleaners are used in these cases.

Utube Projectiles

The utube projectile has the same design as the patented metal projectile, but is smaller and the center is more flexible. These design changes allow these to navigate the bends of a utube heat exchanger. The design of the utube projectile ensures that it is capable of removing both soft and hard tube deposits. For more detailed information on the process of cleaning utube heat exchangers, visit this link.

Internally Enhanced Tubes

Internally enhanced or sometimes called rifled tubes are common in some heat exchangers such as chiller modules. These tube designs help heat transfer but create difficulties for cleaning. Most tube cleaners are designed for smooth bore tubes, but both the nylon brush and the twisted wire brushes can be used on enhanced tubes. The tube deposit should dictate if you use a nylon brush (soft deposits) or if you choose a twisted wire brush (hard deposits) to clean enhanced tubes.

For more information on Projectile Tube Cleaning’s Condenser Tube Cleaning Products and Services, please feel free to contact us: