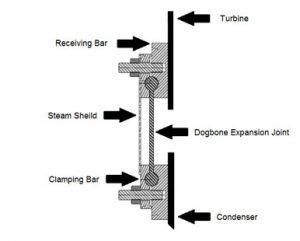

Projectile Tube Cleaning offers both replacement and repair services for condenser expansion joints. Condenser expansion joints, which are also sometimes referred to as dog

Condenser Expansion Joint Inspection and Assessment

Projectile Tube Cleaning can support all condenser expansion joint inspection and assessment needs. Projectile offers air in leakage testing to identify if an expansion joint is beginning to degrade and cause air in leakage. Air in leakage is usually the first and most notable sign of expansion joint failure. This assessment is done while the unit is online. Projectile also offers visual inspections from both the outside and inside of the condenser hotwell. Durometer testing for hardness of the belt can also be used to tell if the expansion joint is out of specification. Typically expansion joint durometers start out in the upper 50’s on the shore A scale and become harder over time. When the belt becomes harder due to old age it becomes more brittle and thus more susceptible to failure.

Condenser Expansion Joint Replacement

Once an assessment on the expansion joint has been performed and it has shown that the condenser expansion joint should be replaced, Projectile Tube Cleaning can help with all aspects of the expansion joint replacement. Projectile condenser expansion joint crews can supply the new expansion joint based on customer drawings. If drawings cannot be provided, onsite measurements

Condenser Expansion Joint Repairs

In some instances condenser expansion joints need replaced, but for economic reasons the plant cannot shut down or

Rubber Expansion Joint Retrofit for Metal Bellow Expansion Joints

Rubber expansion joints can be retrofitted into a condenser that currently has a metal bellow expansion joint. This involves cutting out the plating on the bellow from the hotwell, welding in new clamping bars to the hotwell, and then installing the belt. After the process is completed the space between the old bellow and the new rubber dog bone expansion joint is pressurized between 5-8 psi to ensure none of the welds are leaking. Welds are repaired as needed until the new hardware passes the inspection.

Surf Water Expansion Joint Replacement

Surf water expansion joints are used on circulating water pipe systems going into the condenser water boxes. Many power plant’s circulating water expansion joints are rubber spool-type expansion joints which are located between the condenser water box and the inlet and outlet circulating water piping on the circulating water system. Surf water expansion joints act as a stabilizer to minimize the movement at start up and shut down. The expansion joints come in a variety of sizes. The industry recommends that the circulating water expansion joints should be changed approximately every 10 years. The amount of water going through the circulating water system can be more than 30,000 GPM on a small system to over 1,000,000 GPM on a large system. A leak could be catastrophic if the expansion joint fails during operation. Projectile Tube Cleaning provides full turnkey services for replacement of surf water expansion joints.

Types of Condenser Expansion Joint Failures:

Catastrophic Failure of Expansion Joint

Typically catastrophic failures of expansion joints occur when the system owner waits too long to replace the expansion joint. The typical life of an expansion joint is 10-12 years. Because a failure of an expansion joint can completely shut down a unit, it is a good maintenance practice to replace the belt within its operating life. The picture shown next to this text shows what a catastrophic expansion joint failure can look like. In this instance the ball which is held by the clamping bars completely separated from the rest of the belt and the force of the belt being pulled into the hotwell by the vacuum bent the heat shields backwards. The bent heat shields show the shear force that the expansion joint is subjected to on a daily basis.

Improper Installation Failure

If a condenser expansion joint is not installed correctly using correct procedures, the new belt can leak directly from the outset of the new installation. Errors in installation can be caused for various reasons such as: pinching the dog-bone ball, not using proper sealant, improperly applying sealant, not replacing certain hardware that needed replaced, improper torquing, etc. The

Benefits of Projectile Tube Cleaning Condenser Expansion Joint Replacement Services:

- Complete turnkey replacement of all components. Projectile can supply the following for a full turnkey solution:

- Inspection and assessment services of the expansion joint ahead of any installation plans

- All labor and equipment

- The new condenser expansion joint

- Any new hardware such as clamping bars, heat shields, washers, nuts, studs, etc

- Scaffolding and decking of the condenser hotwell

- Vulcanization of the belt onsite

- Projectile Tube Cleaning can work with Union sites as technical support for Union employees

- Expansion joint replacement services will provide an immediate return on investment in terms of lower back pressure, lower levels of dissolved oxygen, which ultimately will lead to increased system efficiency

- Replacement of the condenser expansion joint will provide a more reliable condenser system